Transforming Health Outcomes - Touching Lives

We are a unique organization with a strong research foundation and unending quest for global leadership in the pharmaceutical and healthcare service space. An organization of passionate professionals who go that extra mile to share excellence and spread joy.

Speed

Proactive and swift action is our mantra.

Innovation

Offering unique & impactful solutions.

Happiness

Success of our stakeholders.

What drives us

- An Innovation-led packaging solutions provider

- We endeavor to deliver effective & affordable solutions

- Protect brands by ensuring genuine medicines to patients.

Focused on Quality, Innovation & Manufacturability

We offer a wide range of speciality polymer films and aluminium foils mainly used for packaging of solid dosage pharmaceutical products.

Barrier strength properties

Barrier against moisture, light, gases etc

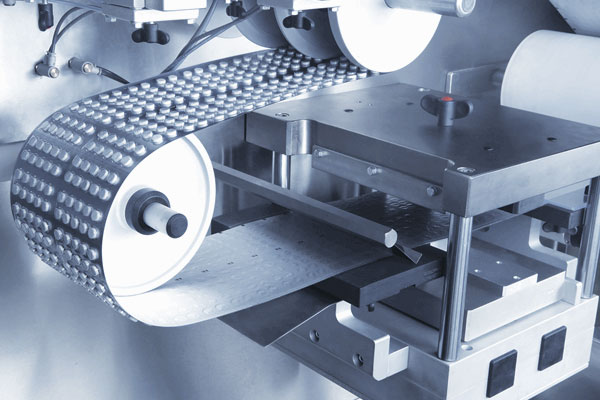

Machinability of materials

Designed for high speed manufacturing

Compatibility with machinery

Compatible with all blister machines

Printability of complex designs

Flexo or rotogravure printing with great detail

Embedded security features

Overt and covert features incorporate uniqueness

Most trusted Pharma packaging Partner globally as a result of Bilcare’s novel 5Cs approach

Bilcare is known around the world for only the best in quality Pharma Packaging materials supplies, and stalwart customer service, regardless of the time zone

1

Convenience

Seamless convenience leads to loyal usage by patients and caregivers

2

Communication

Brand differentiation & recollect is vital among competing brands

3

Compliance

Medication adherence strengthens patient health outcomes

4

Child Resistant

User friendly yet resisting children’s mishap with medication

5

Counterfeiting

Anti-counterfeting features to safe guard leading brands and consumers

Board of Directors

Research & Manufacturing of state of the art

Pune and Nashik plants have an excellent capacities to meet global Pharma packaging solutions needs with flexibility in volumes and specifications.

50000

Tonnes annual manufacturing capacity

1000

Qualified professionals in Pharma & packaging

FDA

State FDA licensed facilities

SOPs

In line with USFDA requirements

ISO

TÜV SÜD audited 9001:2015, 14001:2015, 15378:2017

Classified manufacturing environment under controlled temperature and humidity conditions, conforming to packaging cGMP norms. Equipped with ISO Class 8 clean rooms. Inventory management through 21 CFR Part 11 compliant SAP ECC 6.0.

Strong & reliable long-term partnerships

A global customer base and customers comprise many of the largest global pharmaceutical companies in over 100 countries worldwide

1

Materials

Proactive steps toward environmental impact of industrial materials

2

Recyclability

Recycable polymers and aluminum grades are strongly proposed

3

Emissions

Stringent goals to reduce impact of industrial emissions

4

Processes

Lean strategies and virtues to achieve process efficiencies

5

Cost

Cost-effective approach towards sustainable manufacturing systems

Speed

Proactive and swift action is our mantra.

Innovation

Offering unique & impactful solutions.

Happiness

Success of our stakeholders.

What drives us

- An Innovation-led packaging solutions provider

- We endeavor to deliver effective & affordable solutions

- Protect brands by ensuring genuine medicines to patients.

Focused on Quality, Innovation & Manufacturability

We offer a wide range of speciality polymer films and aluminium foils mainly used for packaging of solid dosage pharmaceutical products.

Barrier strength properties

Barrier against moisture, light, gases etc

Machinability of materials

Designed for high speed manufacturing

Compatibility with machinery

Compatible with all blister machines

Printability of complex designs

Flexo or rotogravure printing with great detail

Embedded security features

Overt and covert features incorporate uniqueness

Most trusted Pharma packaging Partner globally as a result of company's novel 5Cs approach

We are known around the world for only the best in quality Pharma Packaging materials supplies, and stalwart customer service, regardless of the time zone

1

Convenience

Seamless convenience leads to loyal usage by patients and caregivers

2

Communication

Brand differentiation & recollect is vital among competing brands

3

Compliance

Medication adherence strengthens patient health outcomes

4

Child Resistant

User friendly yet resisting children’s mishap with medication

5

Counterfeiting

Anti-counterfeting features to safe guard leading brands and consumers

Board of Directors

Research & Manufacturing of state of the art

Pune and Nashik plants have an excellent capacities to meet global Pharma packaging solutions needs with flexibility in volumes and specifications.

50000

Tonnes annual manufacturing capacity

1000

Qualified professionals in Pharma & packaging

FDA

State FDA

licensed facilities

SOPs

In line with

USFDA requirements

ISO

TÜV SÜD 9001:2015, 14001:2015, 15378:2017

Classified manufacturing environment under controlled temperature and humidity conditions, conforming to packaging cGMP norms. Equipped with ISO Class 8 clean rooms. Inventory management through 21 CFR Part 11 compliant SAP ECC 6.0.

Regulatory

Company Films & Foils comply with global applicable regulatory standards

Current valid EU Pharmacopoeia, USP 661.1

FDA 21 CFR EC 1935/2004, (EU) No. 10/2011

REACH - Regulation (EC) No. 1907/2006

USDMF & Canadian DMF details upon request

Strong & reliable long-term partnerships

A global customer base and customers comprise many of the largest global pharmaceutical companies in over 100 countries worldwide

1

Materials

Proactive steps toward environmental impact of industrial materials

2

Recyclability

Recycable polymers and aluminum grades are strongly proposed

3

Emissions

Stringent goals to reduce impact of industrial emissions

4

Processes

Lean strategies and virtues to achieve process efficiencies

5

Cost

Cost-effective approach towards sustainable manufacturing systems