Bilcare

Triplex

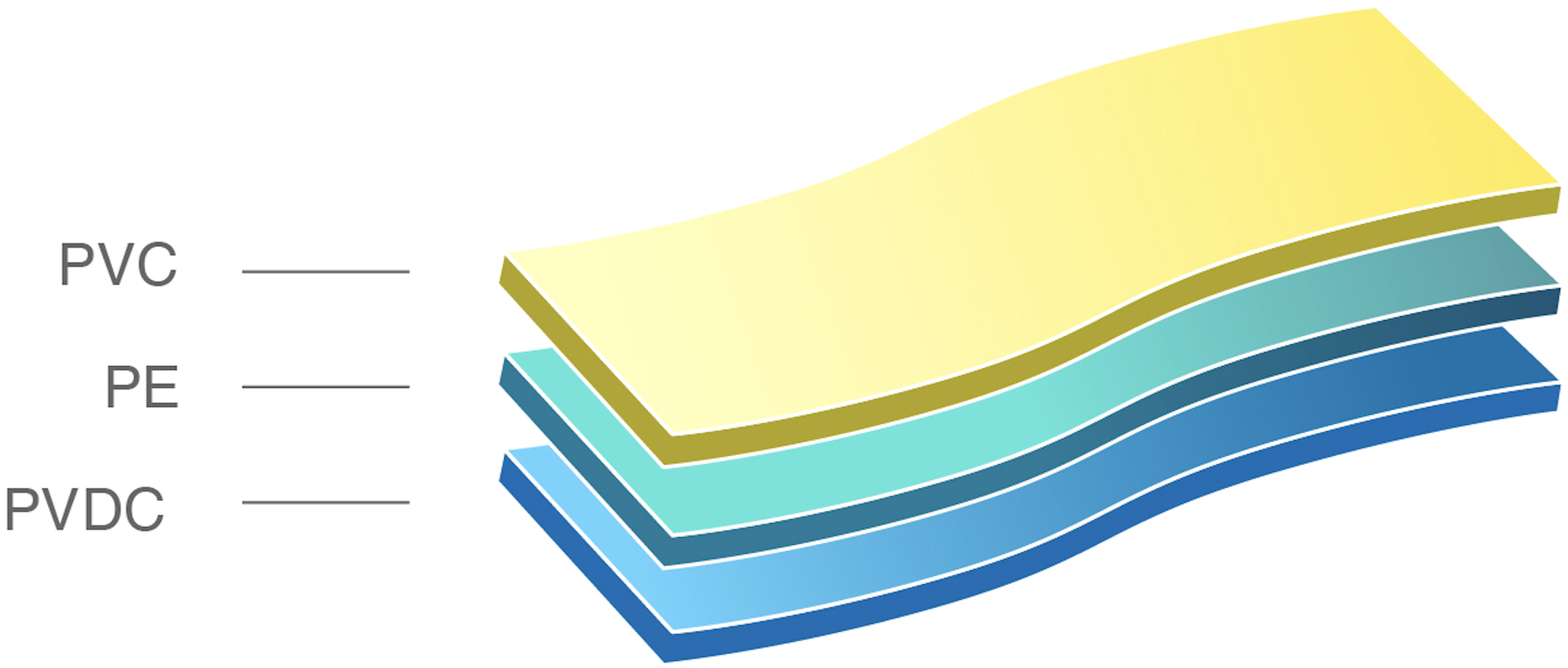

PVC / PE / PVDC

Bilcare TriplexTM is three layer composite provides higher barrier towards moisture, gases and aroma having improved formability

Applications

Suitable for pharmaceutical blister packs having Sensitive formulations like Norfloxacin, Lactic Acids, etc.

Salient Features

- Customised barrier against moisture and gases

- Excellent dart impact and dimensional stability

- Optimum shrinkage ratio

- Excellent thermoforming properties.

- Non-Toxic

- Complies to the international limits for global migration and RVCM content

Technical Data Sheet

Water Vapour Transmission Rate

0.002 mg / cavity

@ 40 °C, 75%RH

Film Thickness

129 ± 10% μ

DIN 53370

Film GSM

207 ± 10% μ

DIN EN ISO 2286

Impact Stregth

min. 700 gm

ASTM D 1709

Heat seal strength

min. 0.3 Kg/cm

PE side to Alu foil

Toxicity

Non Toxic

USP 661

| Property | Test Method | Unit | Specifications |

| Total Thickness | DIN 53370 | micron | 307.0 to 353.0 |

| Total GSM B) For all Opacifying agent films | DIN EN ISO 2286 | gm/m2 | 417.0 to 479.0 426.0 to 490.0 |

| Thickness of Rigid PVC film | DIN 53370 | micron | 238.0 to 263.0 |

| GSM of PVC film b) For all Opacifying agent films | DIN EN ISO 2286 | gm/m2 | 318.25 to 351.75 |

| GSM of LDPE film | DIN EN ISO 2286 | gm/m2 | 21.60 to 25.50 |

| GSM of PVdC coating | DIN EN ISO 2286 | gm/m2 | 86.0 to 96.0 |

| RVCM Content | Council Directive 78/142/EEC | mg/kg or ppm | 1.00 maximum |

| Global migration (Overall migration) | EU No. 10/2011 as amended | mg/dm2 | 10 maximum |

Triplex Variants

| PVC / PE / PVdC |

|---|

| 200 / 25 / 40 | 60 | 90 | 100 | 120 |

| 250 / 25 / 40 | 60 | 90 | 100 | 120 |

Innovation Possibilities

-

Spectra: Flexographic printing on blister side for branding

-

Protect: Differential grating pattern gives holographic visual effect

-

Colours: Glass Clear, Amber, Blue, Green, Orange, Peach, Red, White Opaque, Yellow & other colors upon request.

Additional Information

Printed

| Parameter | Test Method | Unit | Specification |

| Toxicity Test | Current Usp |

| Non Toxic |

| Rub ProofNess Test(20 Rubs at 2 Psi) | In House |

| Should Pass |

| Average No. Of Joints Per Roll/Spools |

| Number | 2 max |

Non Printed

| Parameter | Test Method | Unit | Specification |

| Toxicity Test | Current Usp |

| Non Toxic |

| Average No. Of Joints Per Roll/Spools |

| Number | 2 max |

Slitted

| Inner Diameter of Core | 76mm/152mm |

| Slit Width tolerance | Upper limit +1 and lower Limit -1mm |

| Slit Roll Width | 50mm to 1190mm |

| Packing | Each Slitted Spool Wrapped in Black PE film |

| Labelling | Bar Coded labels containing the product details are fixed inside the core, on stretched wrapped film and finally on the carton .Other label indicating the coated surface is also affixed on the spool |